Sheet Metal Folding London Lingfield Surrey DS Metalworks

Sheet metal part process diagram. The calculation formula for the length dimension L of the neutral layer is: L=L1+L2+Π (180°-β) (r+tk)/180°. Among them, L1, L2 - Length of straight sections (mm); β - Bending angle (°); r - Inner radius of bent plate (mm); t - Thickness of steel plate (mm); k - Neutral layer coefficient.

Sheet Metal Folding Services Yorkshire Profiles

Ideal for folding channels and making long uniform bends and folds in sheet metal Designed to make folds at 3/8" or 1" depths Sight holes to help assure proper depth alignment Specifications Dimensions Assembled Depth (in inches) 0.25 Assembled Height (in inches) 12 Assembled Weight (in lbs) 1.1 Assembled Width (in inches) 4.5

Sheet Metal Folding Services Yorkshire Profiles

Description The Malco folding tool is 18'' long and permits and 3/8'' and 1'' folding depths. The folding seams are formed from two steel halves, permanently joined together. Handy sight holes assure proper depth alignment and the longer folding tool provides a more uniform fold. You may also like MALCO

Sheet metal folding

18" Sheet Metal Folding Tool Home Automotive Auto Body & Trim Metalwork Tools Benders & Rollers SKU: 96523 PITTSBURGH 18 In. Sheet Metal Folding Tool Shop All PITTSBURGH $497 Make uniform folds in sheet metal with this metal folding tool Read More In-Store Only Check Inventory For This Product At a Store Near You You May Also Like

Sheet metal folding evolves

1. What is sheet metal folding? Sheet metal folding is a key stage within sheet metal fabrication, and is the second step in the four-step process, following cutting. Sheet metal folding involves bending the metal to the desired shape that's required for the product you're manufacturing.

sheet metal folding YouTube

1 MALCO FOLDING TOOL,MAKES 3/8 AND 1 IN BEN Item # WWG1ELJ4 Mfr. Model # 1ELJ4 View more View less CATALOGUE PAGE # N/A Availability dates may vary based on the assortment of product in the cart and is not final until you complete your order. Check Availability: Change Location Web Price : $51.17 / EACH Qty: MIDWEST SNIPS

Sheet metal folding evolves

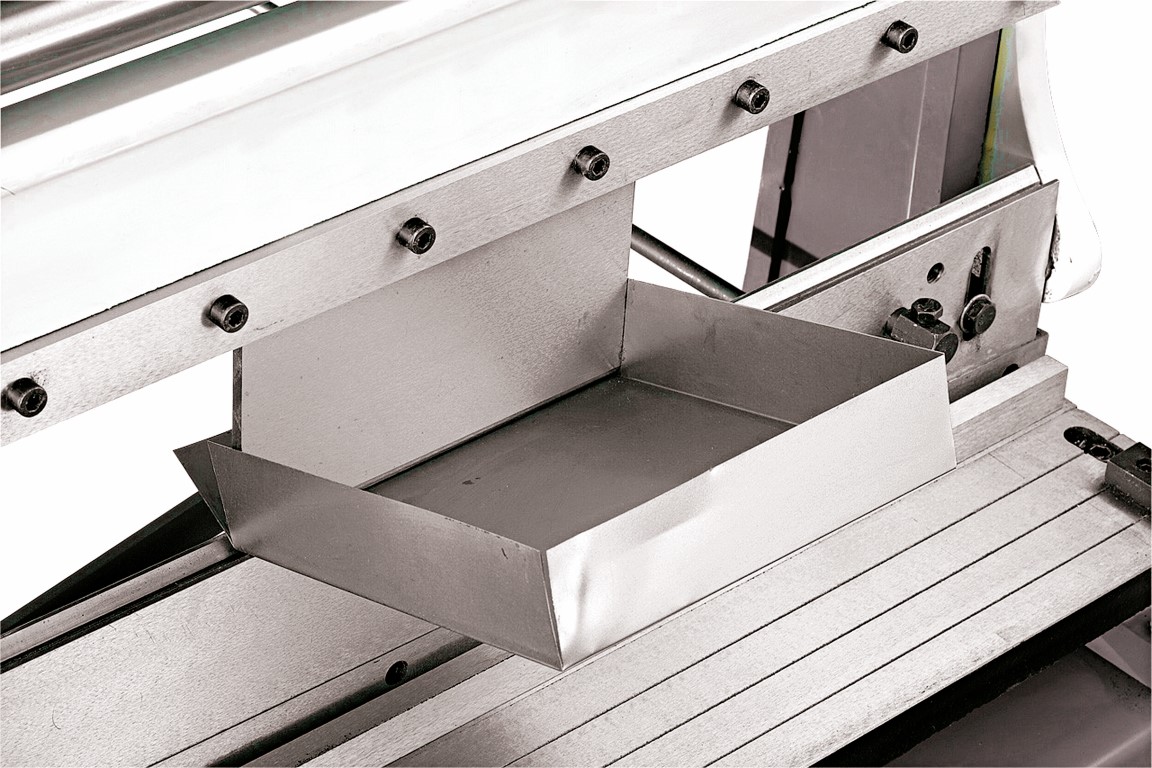

The folding machine is used for bending and forming various metal sheets such as iron, stainless steel, copper, and aluminum. It can also be used as a press machine to complete die forming, riveting, leveling, and other processes. Workpieces are cut and fed by LASER or NCT, and other non-folding shape elements are made by machining, and then.

Tutorial How to Fold Sheets of Metal in Steel and Aluminium Easily Sculpteo Blog

Each sheet metal folding tool model can be used for various applications. Below you can learn more about each model and how it can help on the job site: The 12F model is 12″ (31 cm) long with 3/8″ (9.5 mm) & 1″ (25.4 mm) depths. This tool is ideal for HVAC applications such as folds for drive cleats and big deep folds for joist panning.

Sheet metal folding 5 mustknow basics CSM

What is a sheet metal folding/bending machine? A sheet metal folding/bending machine has a folding beam that bends the metal instead of breaking the metal. This decreases surface markings so finished pieces are cleaner looking and painted parts aren't damaged.

Sheet Metal Folding Machines EBR Metal

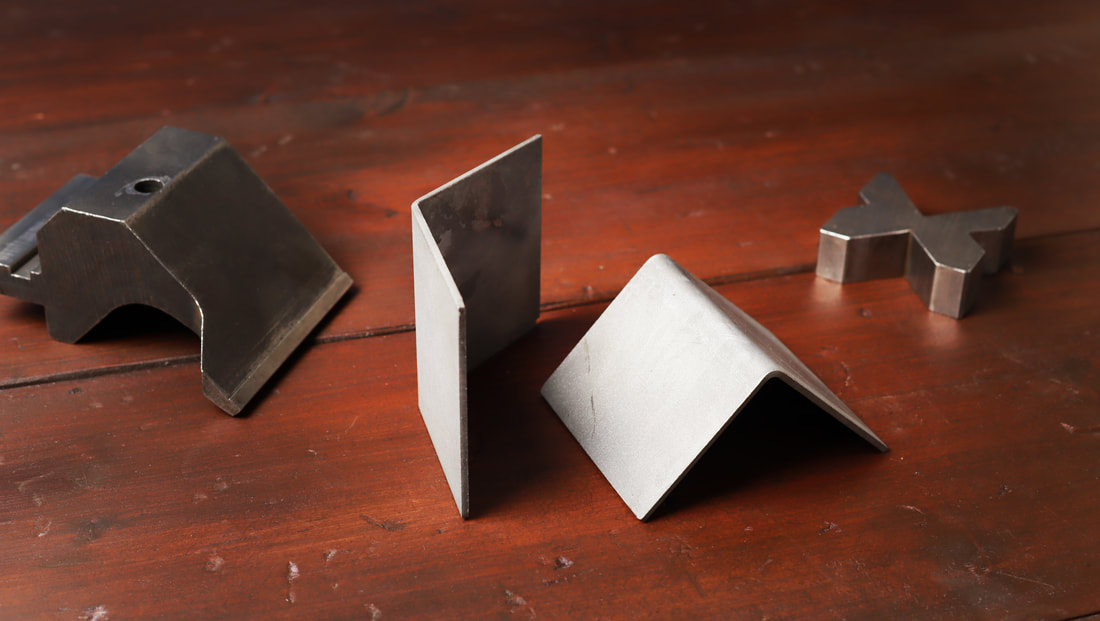

Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material's yield strength to achieve plastic deformation. Only then can you get a lasting result in the form of a bend.

Folding sheet metal work in Great Britain using CNC Press Brakes

M-D Building Products 1 ft. X 2 ft. Aluminium Sheet Mosaic Satin Nickel. Model # MD57005 SKU # 1001343238. (50) $22. 55 / each. Free Shipping over $35. 0 at Check Nearby Stores.

Sheet Metal Folding Service in North Yorkshire Rotbox Rustorations Bespoke Metal Fabricators

A key stage in the fabrication process, sheet metal folding sees a cut piece of high-quality steel bent into the shape required for manufacturing the finished product. The importance of this step, also known as bending, calls for care, attention, and special equipment.

Sheet Metal Folding Machines EBR Metal

During seaming, two sheet metal parts or two edges of the same sheet metal are joined in an interlocking manner. This is done by simultaneously folding or pressing the prepared and fitted edges. According to the DIN 8580 series of standards, this process belongs to subgroup 4.5, joining by forming, and is specified by DIN 8593.

Sheet metal folding evolves

REBEL Folder are perfect folding machines for folding thin metal. They are ideal for roofing industry, HVAC, ventilation plants and more. They are compact, silent and come with accurate electric sheet metal brakes. Exist in COMBI BEAM and STRAIGHT version. REBEL folding machines are perfect for folding thin material : steel, stainless steel, aluminum Compact and silent Low energy consumption.

Sheet Metal Folding Machine Roll Forming Machines LLC

Sheet Metal Joining Methods 1. Folding / Tab Joint. Sheet metal parts can be connected to each other by folding or bending tabs in the form of a buckle and a clamping slot. This method of assembly is simple and convenient, resulting in quick assembly.

Sheet Metal Rolling Brisbane Metal Bending Brisbane Sheet Metal Folding

Nonsparking Ball Peen Hammers. The face and head are made of aluminum-bronze that is Factory Mutual approved, so these tools inhibit sparking, resist corrosion, and are nonmagnetic. Use the domed end of the head for forming soft metal, rounding off edges, and closing rivets. The flat striking face is for driving nails, pins, punches, and chisels.